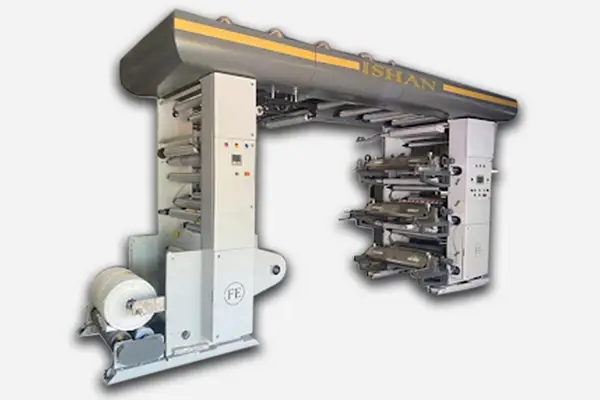

FASTEST ROTOGRAVURE PRINTING MACHINE MANUFACTURER

Since 2000 (Experience in the Printing Machinery Industry for more than 16 years)

Ishan International, headquartered in Ahmedabad, leads as a trusted rotogravure printing machine dealer, supplier, and distributor of high-speed solutions for flexible packaging films, laminates, and more.

Ishan International is a reputable company operating in the flexible packaging sector, which has at its disposal a high level of precision and reliability of the printing technology. Our rotogravure machines have multi-color capability with the ability to achieve high speed, high quality print, and good ink transfer when producing multi-color prints in large quantities. Our engineering and automation capabilities have allowed us to become a prominent Rotogravure Printing Machine Manufacturer in India.

Our rotogravure printing machines have control of web tension accuracy and use energy-saving drying, and give consistency, productivity, and cost savings to industries by printing on BOPP, PET, PVC, paper, and laminated films.

High-Speed Rotogravure Printing Machines Supplier in India for Flexible Packaging

Ishan International offers custom-engineered printing systems, whether in food packaging, in pharmaceuticals, or in decorative films, which are durable, efficient, and innovative. We are a major exporter and a supplier to customers in Africa, the Middle East, and Asia, where we establish the standards of rotogravure printing technologies.

We are an expert in creating efficient and durable rotogravure printing solutions that are highly efficient and one of a kind to meet the changing demands of converting and packaging businesses across the globe. Our machines will be using the advanced intaglio method of printing, which involves densely cutting images, designs, and text onto copper-plated steel cylinders, providing a sharp, consistent, and long-lasting quality print on a wide selection of substrates, such as PET, BOPP, PVC, paper, and foil.

Why Choose Us As your Rotogravure Printer Machines Supplier?

Multi-Color Rotogravure Printing Machine Exporter with High Print Accuracy

Our mission at Ishan International is to attain 100% customer satisfaction. Our Rotogravure Printing Press is made to provide high-performance printing equipment that operates in continuous operation, providing high output at minimal maintenance. Complete with modern control systems, accurate web tensions, and energy-saving drying technology, each machine is capable of high production of quality paper.

We have strongly believed in innovation, customer-centric design, and profound market knowledge, which has made us the preferred destination in most industries like FMCG, pharmaceuticals, cosmetics, and specialty packaging. It is a food-grade material or a high-end flexible film application. If you need reliable equipment that has unequaled performance and longevity, the Rotogravure Printing Machines are the answer provided by Ishan International.

Key Features Of Rotogravure Machine

Top Printing Quality

Creates crisp, consistent, thick image reproduction that is ideally suited to flexible packaging and decorative printing.

Multi-Color Printing Ability

Comes in multi-color mixing, which can be 2 to 10 different colors.

High-Speed Performance

Has a working velocity of 250-350 meters/min with a greater production performance.

Servo Registration Control

Allows automatic tension and alignments and color-to-color accuracy.

ADS (Advanced Drying System)

Combined hot air and IR drying units are available to quickly dry the ink, which enhances the clarity of the print quality and the adhesion.

Web Inspection System (Optional)

Quality control of defect detection in real-time in high-speed runs. Supports water-based ink, water-based inks, or toluene-free inks with limited environmental effects.

Ergonomic design

Easy Set-up, monitoring, and problem solving through a user-friendly HMI /PLC interface.

Modular Construction

It can be customized to suit any future upgrading or expansion, which integrates lamination, slitting, or embossing systems.

MANUFACTURERS OF FLEXO ROTOGRAVURE PRINTING MACHINE WITH SUPERIOR QUALITY AND AFFORDABLE PRICE IN INDIA

Acid is used to cut the images into the plate. Once the copy is photographed, positives are then made from the negatives. The images are transferred to the rotogravure printing machine surface by use of carbon tissue covered with light-sensitive gelatin.

The gelatin hardens based on the amount of light that passes through the positives. A rotogravure printing machine press has one printing unit for each colour, typically CMYK or cyan, magenta, yellow and key (printing terminology for black), but the number of units varies depending on what colours are required to produce the final image.

Technical Specification of FLEXO PRINTING MACHINE

| MODELS | IROTO-2 COLOR | IROTO-4 COLOR | IROTO-6 COLOR | IROTO-8 COLOR | IROTO-10 COLOR |

| Printing Possibilities | 2 Color | 4 Color | 6 Color | 8 Color | 10 Color |

| Web Width* | 500mm to 1600mm | ||||

| Max Cylinder Circumference | 350mm to 800mm | ||||

| Mechanical Speed** | 150 to 250 meters/minute | ||||

Topmost Manufacturer of Rotogravure Printing Machine In Ahmedabad, India

We are determined to offer High-Speed Computerized Rotogravure Printing Machines in ahmedabad to our respected clients. The special features of our machines include that, these machines provide printing support on various types of bags.

The other features of the machines include being made of the best quality raw material and components, corrosion resistant, easy to operate, low maintenance, energy efficient, and longer service Life. It is a kind of ideal printing equipment for producing paper packing bags for food, supermarket handbags, vest bags, and clothes bags. Our organization has gained recognition for providing premium quality Rotogravure Printing Machines.

Technical Specification of Gravure Printing Machinery

| Parameter | Specification |

| Printing Width | 800 mm to 1500 mm |

| Printing Speed | Up to 300 meters per minute |

| Number of Colors | 4 to 12 color stations |

| Drying System | Hot Air, Infrared (IR), or Ultraviolet (UV) Options include |

| Registration System | Auto Electronic Web Guide System |

| Unwinding/Rewinding System | Up to 800 mm |

| Unwind & Rewind Shaft | Air Shaft with Pneumatic Brakes |

| Tension Control | Fully Automatic Web Tension Control with Load Cell Feedback |

| Drive System | AC Vector Drive / Servo Motor Drive (energy efficient) |

| Print Repeat Range | 450 mm to 1000 mm (extendable up to 1200 mm on demand) |

| Drying Source | Electrical, Thermic Fluid, or Gas |

| Power Consumption | Energy-efficient, customizable based on specific requirements |

| Printing Cylinder | Quick Change Sleeve Type / Conventional Type |

| Ink Circulation | Enclosed Chambered Doctor Blade System / Open Pan System |

| Power Requirement | 380V – 440V, 3 Phase, 50/60 Hz (as per client requirement) |

Our Product Range

How the Rotogravure Printing System Works?

Photo Engraving on Cylinder

The design/image is plated as a series of tiny cells (microscopic depressions) on a copper-coated steel cylinder. The size and depth of these cells define the capacity they are able to hold the ink. Lighter cells; darker cells = deep cells.

Ink Application

The cylinder, engraved, accepts ink in a fountain (an ink tray containing ink). The whole cylinder area (cells and non-image area) is covered with ink.

Doctor Blade Action

The surface is wiped clean by a doctor's blade (a thin blade of steel). It washes away the ink in the non-engraved places, leaving ink only in the engraved cells.

Substrate Contact

The paper, film, foil, or other substrate moves between the engraved cylinder and an impression roller. Ink is transmitted to the substrate with high pressure in the cells.

Drying System

Rotogravure is printed with liquid solvent or water-based inks, and so the substrate is processed through a hot air drying system. This dries solvents and dries the ink between colors being added.

Multi-Color Printing

In colored printing, the substrate will run through several units (one per color, CMYK or spot colors). The registration controls make sure that the colors are aligned.

Rewinding / Finishing

The substrate is rewound into rolls after printing and drying, or handed over to cutting/lamination as per end use.